Introduction

Starting a one-person metal mold design business can be a lucrative and fulfilling venture for those with a passion for craftsmanship, engineering, and creativity. In an industry that serves a wide range of sectors, from automotive to consumer goods, metal mold design is an essential skill for producing high-quality, precise parts. If you’re thinking about starting this business, you’ve come to the right place. In this guide, we’ll walk you through the key steps to launch your own successful one-person metal mold design business.

1. Understanding the Basics of Metal Mold Design

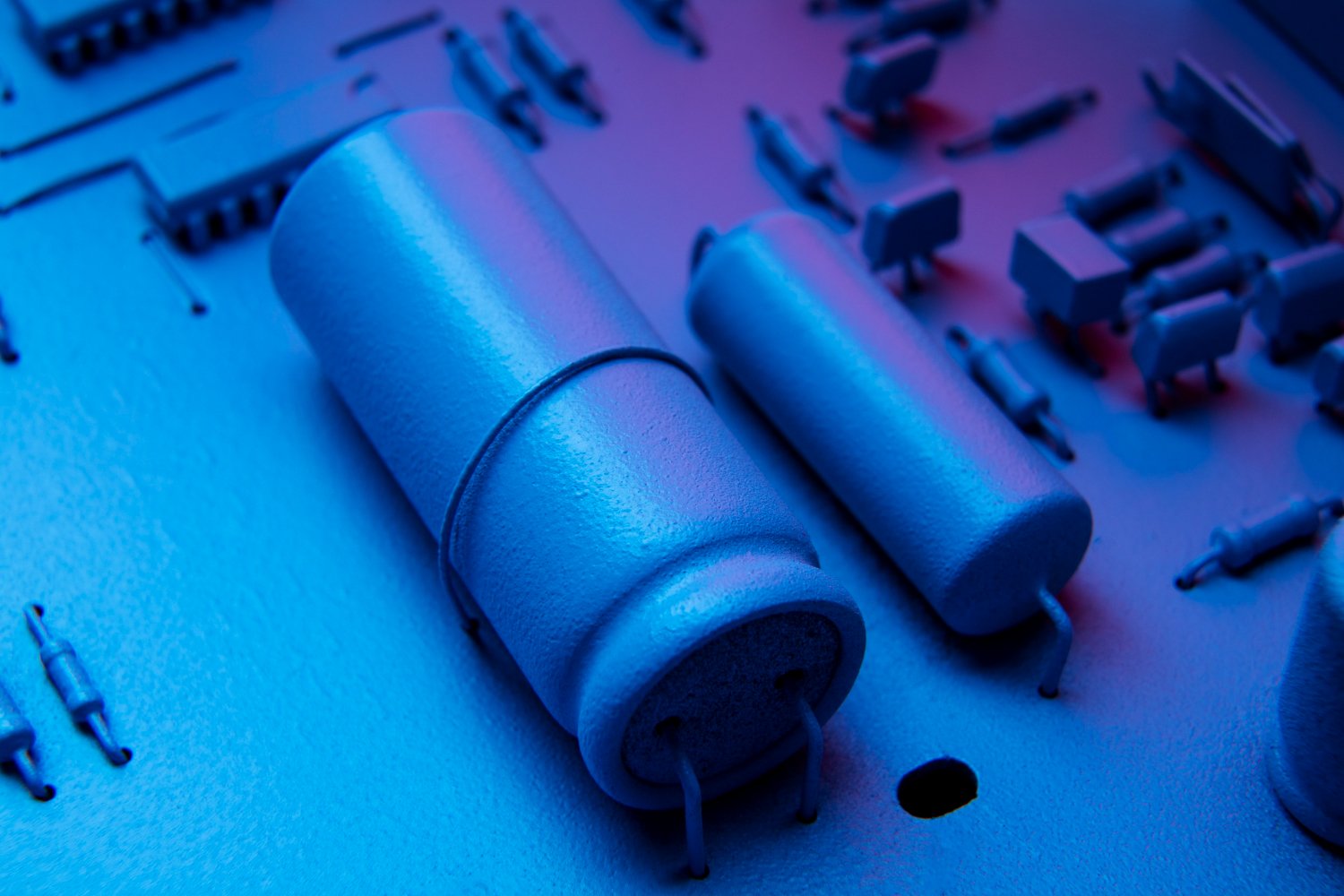

Metal mold design involves creating molds that are used to shape and form metal parts during manufacturing. These molds are typically used in industries like automotive, aerospace, and electronics. The process requires precision, attention to detail, and a solid understanding of material science and engineering principles.

Key Skills Needed:

- Proficiency in CAD software (e.g., AutoCAD, SolidWorks).

- Knowledge of mold-making materials (e.g., steel, aluminum).

- An understanding of mechanical properties and manufacturing processes.

2. Setting Up Your Business

Business Plan and Niche Focus

Before diving into the practicalities, you need to create a solid business plan. This plan should detail your services, target market, pricing strategy, and operational costs. Focus on a niche within metal mold design that aligns with your strengths or interests. For example, specializing in molds for custom parts for the automotive industry or creating molds for small consumer goods could help you stand out in the market.

Business Structure and Legal Considerations

Next, you’ll need to decide on the structure of your business—whether you want to operate as a sole proprietorship, LLC, or corporation. Most one-person businesses operate as LLCs due to liability protection and tax advantages.

Register your business with the relevant local or state authorities. You will also need the necessary licenses and insurance to protect yourself from potential legal issues and accidents during the manufacturing process.

3. Investing in Equipment and Tools

As a one-person business, you’ll need to invest in high-quality tools and machinery. The equipment required for metal mold design varies depending on the complexity of the molds you plan to make.

Essential Tools:

- Computer-Aided Design (CAD) Software: This is essential for designing precise and accurate molds.

- CNC Milling Machine: A computer-controlled machine that shapes metal with high precision.

- 3D Printer (Optional): For prototyping and testing designs before committing to metal molds.

- Measuring Instruments: To ensure your molds meet precise dimensions.

Investing in the right tools is critical for the success of your business. Even as a solo entrepreneur, having professional-grade equipment will ensure you can deliver high-quality work to clients.

4. Building Your Brand and Online Presence

In today’s digital age, a strong online presence is crucial. You should create a professional website that showcases your portfolio, services, and contact information. Include details about your expertise in metal mold design and any specializations you offer.

Social Media and Online Marketing: Utilize platforms like LinkedIn, Instagram, and Facebook to share your work and engage with potential clients. By showcasing before-and-after photos of your molds and the end products, you can build credibility and attract new customers.

Search Engine Optimization (SEO): Optimize your website content with relevant keywords, such as “best one-person metal mold design business,” to improve your visibility on search engines. This will help potential clients find you when searching for mold design services.

5. Pricing Your Services

Setting competitive yet profitable pricing is key to maintaining a sustainable business. Research the going rates for metal mold design in your area and industry.

Pricing Strategies to Consider:

- Hourly Rate: Charge clients by the hour based on the complexity of the design.

- Project-Based Pricing: Offer fixed rates for each project, based on the scope and size of the mold required.

- Retainer Models: For long-term clients, you could consider a retainer model, where clients pay a monthly fee for ongoing services.

Make sure your pricing covers the costs of materials, equipment, software, and your time, while also allowing for profit.

6. Networking and Building Client Relationships

Although you are operating as a one-person business, networking is still crucial for success. Attend industry events, join online forums, and connect with other professionals in the mold design and manufacturing sectors.

Client Relationship Tips:

- Communication: Keep your clients updated on progress and timelines.

- Quality Assurance: Offer guarantees or warranties on your work to instill trust in your clients.

- Follow-Up: Stay in touch with past clients for potential future projects or referrals.

Conclusion

Starting the best one-person metal mold design business requires a mix of technical expertise, business acumen, and creativity. By focusing on quality, networking, and leveraging the right tools, you can carve out a successful niche in this highly specialized industry. Whether you’re designing molds for a small business or large-scale production, there’s plenty of room for growth and innovation.

With the right planning and execution, your one-person business can thrive and provide valuable services to a wide range of industries.

FAQs

1. What is the primary skill required for metal mold design?

The primary skill needed is proficiency in CAD software, which allows you to design precise molds. A solid understanding of materials and manufacturing processes is also essential.

2. How much does it cost to start a one-person metal mold design business?

The costs can vary depending on the equipment and software you choose. On average, expect to spend anywhere from $5,000 to $30,000 for tools, machines, and licenses.

3. Can I run this business from home?

Yes, many metal mold designers operate from home, especially in the early stages. However, you’ll need adequate space for equipment and a workshop to handle the design and prototyping work.

4. What industries require metal mold design?

Key industries include automotive, electronics, aerospace, consumer goods, and even medical devices, all of which rely on precise, high-quality molds for manufacturing parts.

5. How long does it take to complete a mold design project?

The timeline depends on the complexity of the mold and client requirements. Simple designs may take a few days, while more intricate molds can take several weeks.